AUTOTRONIK-SMT

the experts in SMT technology. From the SMT pick and place machine to the SMT stencil printer. We have been one of the leading manufacturers of automatic pick and place machines for the electronics industry for well over 15 years.

AUTOTRONIK-SMT is a globally active company with around 200 employees. We are your SMT specialist for stencil printers, pick and place machines and reflow ovens of small to medium series as well as complete SMT production lines. Our global commitment allows us to bring together the best components from all continents into an outstanding product.

This enables us to use techniques that are otherwise only used in high-volume machines. This allows us to offer fair

conditions, despite special features such as

- welded steel frame structures

- Prisms supported “Vision on the Fly” centering

- as well as non-contact linear encoder systems with AC motors

SMT pick and place machine from AUTOTRONIK-SMT

All assembly systems have been developed for the flexible production of SMT projects. During the development of the systems, short changeover times, e.g. thanks to barcode support and a modular structure, so that all available options can be retrofitted at the customer’s site.

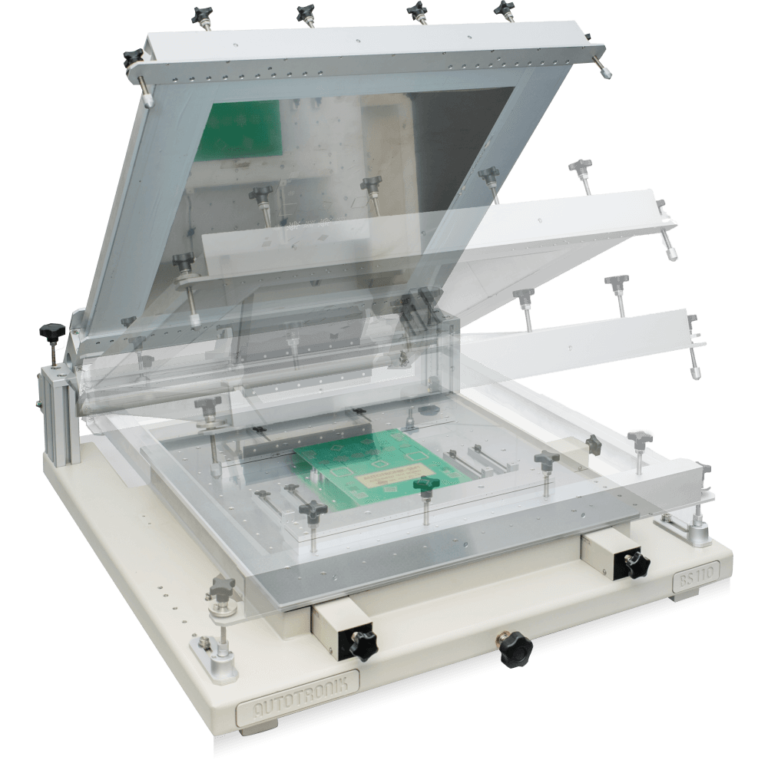

SMT Stencil Printer

The unstoppable tendency towards ever finer structures and smaller components makes ever more perfect results than requirements In order to meet these requirements, the quality of the end product corresponds to the precision of the solder paste printing. AUTOTRONIK-SMT manufactures manual, semi-automatic and fully automatic stencil printers that achieve the highest accuracy and are easy for the operator to use. Use our devices to print the finest structures precisely and reproducibly. We focus on quality and the ratio of costs to benefits.

SMT Stencil Printer - from manual up to automatic inline printer

Our spectrum ranges from manual stencil printers for prototype production for small and medium quantities to fully automatic systems.

During the development of the systems, short changeover times, e.g. thanks to barcode support and a modular structure, so that all available options can be retrofitted at the customer’s site.

Reflow Oven

Benchtop-Reflow oven BT301

The BT301 Benchtop-Reflow oven is ideal for use in laboratories / small series or for determining soldering profiles.

The BT301 Benchtop-Reflow oven is ideal for use in laboratories / small series or for determining soldering profiles.

Accessories SMT technology

The placement machines from AUTOTRONIK-SMT can be equipped with a variety of additional accessories.

For feeding components, you can choose between KFTA feeders, KFTB feeders, belt section holders, feeder carriage and tray holders

There is also the option of feeding bulk material, whereby the position and position is determined by our camera system.

In addition, of course, we also offer you every type of inline product, e.g. Loader and unloader or inspection belts

Do you have any questions?

We are here for you!

Available daily by telephone at:

+49 (0) 9621 – 600 691

Monday-Friday:

8:30 to 17:00

Do you need support?

In urgent cases, please call us at immediately. If you are already in possession of access data of your support, you can also use the following online help.